30 Years of Expertise in SMC Sheet Production and Custom Composite Solutions

Company Profile & Core Strengths

We are a professional manufacturer specializing in SMC (Sheet Molding Compound) materials with over 30 years of production experience. With deep expertise in composite materials, we deliver high-performance and cost-effective SMC products tailored to industry needs. Leveraging strong R&D and flexible production, we offer SMC sheets with various strength levels and provide custom processing based on your drawings — including color customization for product or brand matching.

Our factory features advanced automated lines and strict quality control, ensuring consistent SMC materials. We serve industries including water tanks, electrical, automotive, construction, and infrastructure. Whether you need lightweight, impact-resistant panels or flame-retardant options, our team customizes formulations to meet your needs.

Innovation is a key focus. Our engineers constantly enhance durability, reduce weight, and improve sustainability. With ongoing investment in R&D and equipment, we help clients boost performance and stand out in the market.

If you need a reliable partner for consistent, customized SMC materials, we’re ready to support your success.

Tailored Testing of SMC Sheets to Meet Your Product Demands

To ensure that our SMC sheets meet the performance requirements of different applications, we conduct comprehensive laboratory testing tailored to specific product demands. Our in-house testing capabilities cover key mechanical properties, including:

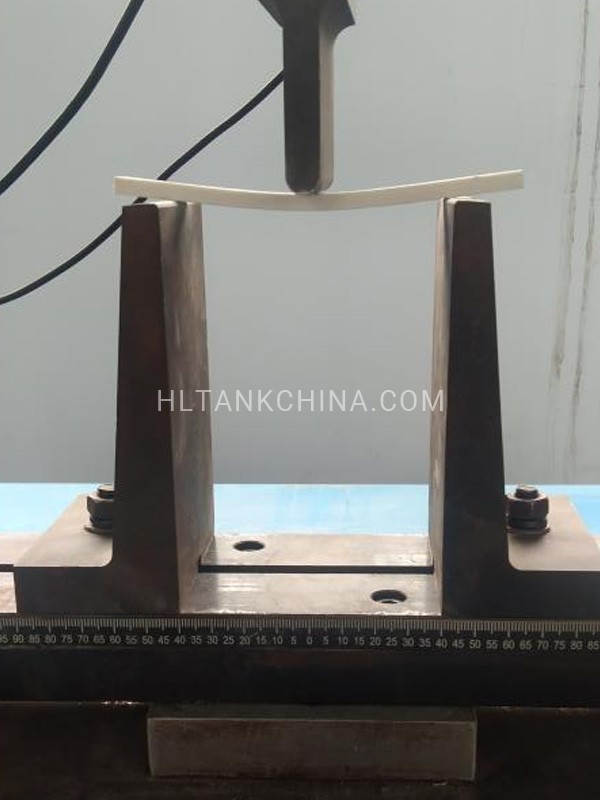

Flexural Properties Testing

Tensile Properties Testing

Compressive Properties Testing

Different Results showing to match your different fiberglass products custom

GB/T 1449-2005 Flexural Strength Test – Sample Taken from the Middle of the Plate

Flexural Properties Testing – Evaluates the material’s bending strength and stiffness under load.

| Sample No | Sample Width (mm) | Sample Thickness (mm) | Maximum Load (N) | Flexural Strength (MPa) |

|---|---|---|---|---|

| 1 | 14.74 | 5.09 | 578.00 | 181.63 |

| 2 | 14.88 | 4.90 | 588.50 | 197.67 |

| 3 | 14.84 | 4.88 | 557.40 | 189.13 |

| 4 | 14.75 | 5.22 | 638.50 | 190.64 |

| 5 | 14.75 | 5.00 | 605.50 | 197.04 |

| Average | / | / | 593.50 | 191.22 |

GB/T 1447-2005 Tensile Strength Test – Sample Taken from the Middle of the Plate

Tensile Properties Testing – Measures the resistance of the sheet to being pulled apart, reflecting its strength and elongation.

| Sample No | Sample Width (mm) | Sample Thickness (mm) | Failure Load (N) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 1 | 24.78 | 5.15 | 11406.0 | 89.37 |

| 2 | 24.62 | 4.93 | 13362.0 | 110.08 |

| 3 | 24.73 | 4.93 | 12202.0 | 100.08 |

| 4 | 24.68 | 4.96 | 11848.0 | 96.79 |

| 5 | 24.72 | 5.00 | 12780.0 | 103.40 |

| Average | / | / | 12319.6 | 99.94 |

GB/T 1448-2005 Compressive Strength Test – Sample Taken from the Middle of the Plate

Compressive Properties Testing – Determines how the material behaves under compressive forces, ensuring structural integrity.

| Sample No | Sample Width (mm) | Sample Thickness (mm) | Failure Load (N) | Compressive Strength (MPa) |

|---|---|---|---|---|

| 1 | 24.78 | 10.11 | 6787.0 | 122.95 |

| 2 | 24.62 | 9.93 | 6581.0 | 132.55 |

| 3 | 24.73 | 10.09 | 6582.5 | 121.72 |

| 4 | 24.68 | 10.14 | 5797.0 | 103.19 |

| 5 | 24.72 | 10.13 | 10392.0 | 182.22 |

| Average | / | / | 7227.9 | 132.53 |

Product advantages

SMC Sheets in Multiple Strength Grades

Depending on your application—be it in power systems, automotive, sanitary ware, water tanks, or construction—we offer SMC sheets in various formulations and thicknesses, from general-purpose to high-strength grades. Whether you require high mechanical strength, heat resistance, flame retardancy, or excellent electrical insulation, we can provide the optimal material solution.

Color Customization Available

In addition to mechanical and functional customization, we offer custom color matching for both SMC sheets and finished molded products. Whether you need a specific RAL color, a brand-specific tone, or a unique aesthetic appearance, our color-matching process ensures that your products not only perform well but also look exactly the way you envision.

Custom Processing Based on Drawings

Equipped with advanced molding equipment and an experienced team, we support custom manufacturing based on client drawings. We can produce various SMC components such as water tank panels, cable trays, manhole covers, and automotive parts. Simply provide your design or sample, and we’ll take care of the rest—from prototyping to mass production.

Reliable Quality Backed by 30 Years of Experience

Our company adheres to strict quality management standards, with all products produced and tested in accordance with ISO regulations. With decades of technical accumulation, we ensure consistent product performance and high processing precision. Our products are highly recognized by customers and exported to Southeast Asia, the Middle East, Europe, and other regions.

Some custom SMC/GRP/FRP water tank parts

As a professional SMC/GRP/FRP (Glass Reinforced Plastic, or fiberglass) water tank manufacturer, we extend our expertise beyond tank panels by offering a wide range of customized fiberglass-reinforced products tailored to your project needs. Whether you’re building structural frameworks, support systems, or access solutions, we provide precision-molded components that deliver strength, durability, and corrosion resistance in challenging environments.

Our custom SMC/GRP/FRP product range includes:

SMC/GRP/FRP I-Beams & C-Channels – Ideal for structural support and framing in water tank installations, platforms, and walkways. These fiberglass-reinforced components are lightweight yet high-strength, and offer excellent resistance to moisture, corrosion, and chemical exposure.

SMC/GRP/FRP Ladders for water tank– Designed with fiberglass material for enhanced durability and safety, our ladders come in various sizes and configurations to meet access, inspection, and maintenance requirements for water tanks.

SMC/GRP/FRP Pipes – Made from corrosion-resistant fiberglass composites, these pipes are easy to install and widely used to support the roof water tank panels.

SMC/GRP/FRP Box Sections – These fiberglass-based box sections are versatile components used in modular construction and custom frameworks, providing superior load-bearing strength and dimensional stability.

SMC/GRP/FRP Angle Profile – Our fiberglass-reinforced angle profiles are perfect for edge framing and corner support. They offer a high strength-to-weight ratio, weather resistance, and ease of installation for both indoor and outdoor use.

……

GRP/FRP I-Beam

GRP GRP/FRP C-Channel

GRP/FRP pipes

GRP/FRP box section

GRP/FRP angle profile

All GRP/FRP/SMC components can be produced according to your drawings or specifications, with options for color matching and surface treatments. With our in-house mold-making capabilities and experienced fabrication team, we ensure fast turnaround times and consistent quality.

Whether you’re upgrading an existing installation or designing a new system, our custom GRP/FRP/SMC solutions provide the strength and flexibility you need.

More FRP fiberglass custom product fabrication applications

As a professional SMC/GRP/FRP (Glass Reinforced Plastic, or fiberglass) water tank manufacturer, we also offer a broad selection of customized fiberglass-reinforced components for a wide range of applications.

Beyond water tank panels, our molded and fabricated SMC/GRP/FRP products are used in:

Electrical: Insulation enclosures, cable trays, and meter boxes

Construction: Formwork, safety barriers, and structural panels

Automotive: Engine hoods, door panels, and roof components

Municipal Infrastructure: Manhole covers, inspection chambers, and pipe systems

Sanitary Ware: Bathtubs, shower trays, and washbasins

These precision-molded components offer exceptional strength, durability, and corrosion resistance, even in the most demanding environments.

Other custom GRP/FRP/SMC fiberglass products

In addition to GRP/FRP/SMC structural profiles and water tank components, we also offer a variety of specialized GRP/FRP/SMC products designed to meet specific needs in electrical, infrastructure, and environmental applications. All items can be tailored in size, color, and performance specifications to suit your project.

GRP/FRP Submarine Cable Protection Pipe (Articulated Split Pipe)

The GRP/FRP Submarine Cable Protection Pipe, also known as Articulated Split Pipe, is specially engineered to protect submarine communication cables, power cables, and pipelines in challenging marine environments. Manufactured from high-strength Glass Reinforced Plastic (GRP) or Fiber Reinforced Plastic (FRP), this split pipe solution offers superior resistance to corrosion, mechanical impact, and seabed movement, significantly extending the service life of underwater infrastructure.

Key Features:

High-Strength Design

The articulated and split structure ensures robust mechanical protection, especially against trawling and anchor dragging.

Corrosion Resistance

GRP/FRP material provides excellent resistance to seawater, acids, and chemicals.

Lightweight & Easy Installation

Lighter than steel alternatives, reducing the need for heavy lifting equipment and lowering installation costs.

Flexible & Modular

Articulated joints allow for flexibility and adaptation to varying seabed profiles.

Eco-Friendly Material

Non-toxic, non-conductive, and environmentally safe—ideal for long-term ocean deployment.

GRP/FRP Protection Cases for Electricity Post Poles

The GRP Protection Case for Electricity Post Poles is a high-strength, weather-resistant enclosure designed to protect utility poles—especially those made of concrete, steel, or wood—from environmental damage and physical impact. These cases are manufactured using Glass Reinforced Plastic (GRP), a composite material known for its corrosion resistance, high durability, and lightweight properties.

In addition to safeguarding poles from corrosion, moisture, and UV exposure, these protective cases also serve as anti-collision barriers, minimizing structural damage in the event of accidental vehicle impact in roadside or urban installations.

Key Features:

Impact-Resistant Design

Acts as a protective shell, absorbing impact forces from collisions (e.g., vehicles, forklifts, machinery) and reducing risk of pole failure.

Corrosion & UV Resistant

GRP materials offer excellent resistance to sunlight, acid rain, chemicals, and salt-laden environments—ideal for coastal, industrial, or rural settings.

Weatherproof & Durable

Can withstand extreme temperatures, high humidity, and strong winds without deformation or degradation.

Modular Split Structure

Typically designed as a two-piece (front and back) case that can be clamped around existing poles without the need for dismantling or interrupting service.

Customizable Dimensions

Available in various sizes, colors, and thicknesses to suit different types of poles and customer branding.

GRP/FRP Septic Tanks

The GRP/FRP Septic Tank is a prefabricated, underground wastewater treatment tank made from FiberGlass Reinforced Plastic (GRP/FRP). Designed to handle household and industrial sewage in areas without centralized sewage treatment systems, this tank is an ideal solution for residential buildings, schools, hospitals, factories, and remote facilities.

Compared with traditional concrete or steel septic tanks, GRP/FRP septic tanks offer superior durability, ease of transportation and installation, and excellent resistance to corrosion, leakage, and environmental degradation.

Key Features:

Corrosion-Resistant

Resistant to acids, alkalis, sewage gases (like hydrogen sulfide), and soil chemicals—no rust or decay over time.

Lightweight & Easy to Transport

Significantly lighter than concrete tanks, which reduces transportation and installation costs.

High Strength & Load Capacity

Reinforced ribbed structure or dome-shaped design ensures high mechanical strength, suitable for underground burial.

Long Service Life

Designed for over 30 years of underground use with minimal maintenance.

Eco-Friendly Solution

Promotes safe sewage disposal, protects groundwater, and supports decentralized sanitation systems.

Tailor-Made SMC Custom Components – Engineered to Your Requirements

We offer advanced customization services for SMC (Sheet Molding Compound) custom components, engineered to meet your specific mechanical, thermal, and dimensional requirements. Our in-house technical team supports full-process development — from CAD design and mold fabrication to material formulation and mass production. We provide high-strength, corrosion-resistant SMC products for applications in water tanks, electrical enclosures, and structural panels. With strict quality control and international standard compliance, we ensure that every custom product performs reliably in demanding environments.

Flexible Cooperation Options

We welcome OEM/ODM partnerships, bulk orders, and small batch customizations. Whether you are a trading company, end user, or product development firm, we offer timely response and professional service to support your product launch and market expansion.

Feel free to contact us for samples, technical data, or a quotation. We are ready to provide you with reliable, aesthetic, and high-quality SMC solutions — tailored in strength, shape, and color to your specific needs.

Just drop me email [email protected] or text Whatsapp:+8618505343912

Stay In Touch With Us