Korea Type GRP Water Tank Features?

Material:

Made from Glass Reinforced Plastic (GRP), also known as Fiberglass Reinforced Plastic (FRP), which is highly durable and corrosion-resistant.

Modular Panel Design:

Typically constructed using modular panels, making it easy to customize the size and shape to meet specific requirements.

Hygienic & Safe for Drinking Water:

Manufactured to meet hygienic standards, ensuring clean and safe water storage.

Non-toxic and does not leach harmful substances into the water.

Corrosion & UV Resistance:

Unlike steel tanks, GRP tanks do not rust and are resistant to UV radiation, making them suitable for outdoor use.

Lightweight & Easy Installation:

Compared to concrete and steel tanks, GRP tanks are lighter, making transportation and installation more convenient.

Applications:

Used in municipal water supply, fire-fighting systems, agriculture, commercial buildings, and industrial facilities.

Korea Panel GRP Sectional Water Tank Made in China

You specialize in the design of Korean FRP (Fiberglass Reinforced Plastic) water tanks and offer both OEM and ODM services. Here’s a detailed breakdown of your expertise:

OEM (Original Equipment Manufacturing)

Clients provide the design, specifications, and branding, while you handle manufacturing.

Ensures compliance with international standards such as SS245, ISO 9001, and other relevant certifications.

Suitable for industries requiring durable, corrosion-resistant, and lightweight water storage solutions, including municipal projects, industrial applications, and commercial buildings.

ODM (Original Design Manufacturing)

You not only manufacture but also offer complete product design and technical development.

This includes structural optimization, enhanced resin formulations, improved UV resistance, and customized modular assembly solutions.

Provides clients with end-to-end solutions, from product development to mass production, ensuring high performance and durability.

Advantages of Korean FRP Water Tank Design

High Strength & Durability – Engineered to withstand harsh environmental conditions, including extreme temperatures and chemical exposure.

Lightweight & Corrosion-Resistant – Ideal for applications where traditional steel tanks may face corrosion issues.

Flexible & Customizable – Modular design allows for easy transportation, assembly, and customization based on client requirements.

Energy-Efficient & Sustainable – Manufactured using advanced resin technologies to reduce environmental impact while ensuring longevity.

Korea GRP panel

Foam sealing tape

Stainless steel flanges

External ladder

C-channel skid base

Internal lacing bar board

lacing bar

Adjustable support base(optional)

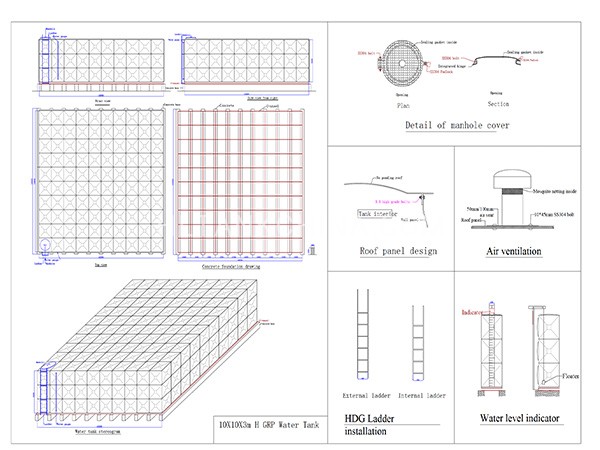

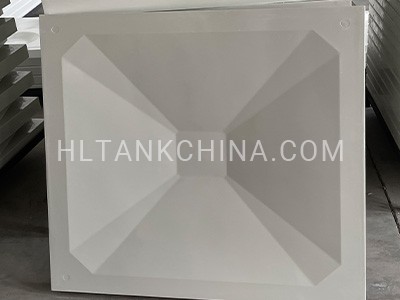

1. Korea GRP Panel

Function: A high-strength, lightweight panel used for constructing GRP (Glass Reinforced Plastic) water tanks.

Material: Fiberglass reinforced plastic, known for its corrosion resistance, durability, and lightweight nature.

Application: Commonly used in industrial, commercial, and municipal water storage applications, ensuring long-term performance in various environmental conditions.

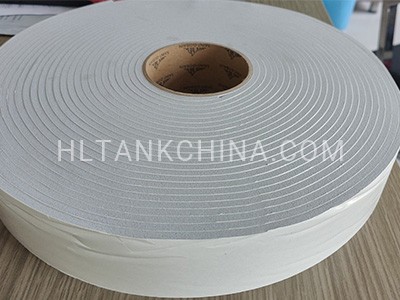

2. Foam Sealing Tape

Function: Used for sealing between water tank panels to prevent water leakage and provide cushioning.

Material: Usually made of EPDM, PE, PU, or silicone foam, offering waterproof, weather-resistant, UV-resistant, and high-temperature-resistant properties.

Application: Essential for modular water tank assembly, ensuring a secure and watertight seal.

3. Stainless Steel Flanges

Function: Used for connecting pipes and fittings to the water tank, ensuring a secure and leak-proof joint.

Material: Stainless steel (SS304/SS316), offering high corrosion resistance.

Application: Suitable for both potable water and industrial applications, ensuring reliable water flow and system integration.

4. External Ladder

Function: Provides safe access for maintenance and inspection of the water tank.

Material: Galvanized steel, stainless steel, or aluminum, with optional anti-slip rungs.

Application: Installed on large tanks where regular inspections or cleaning are required, compliant with safety regulations.

5. C-Channel Skid Base

Function: Serves as a structural foundation for the water tank, elevating it off the ground to prevent corrosion and improve stability.

Material: Hot-dip galvanized steel or stainless steel, providing rust resistance and durability.

Application: Used in industrial and commercial water tanks where a strong base is required to distribute load evenly.

6. Internal Lacing Bar Board

Function: Strengthens the internal structure of the tank, preventing deformation due to water pressure.

Material: Galvanized steel or stainless steel.

Application: Essential for large or high-capacity water tanks, ensuring long-term structural integrity.

7. Lacing Bar

Function: Provides additional reinforcement and bracing inside the tank, supporting panels against internal water pressure.

Material: Galvanized steel or stainless steel, designed for heavy-duty applications.

Application: Used in modular panel water tanks, ensuring high durability under various pressure conditions.

8. Adjustable Support Base (Optional)

Function: Provides adjustable height and leveling support for the water tank, especially on uneven ground.

Material: Galvanized steel or stainless steel, with adjustable bolts for precise height control.

Application: Ideal for installations on irregular terrains, offering flexibility and stability.

How to make one Korea GRP water tank panel?

1. Raw Material Preparation: Pre-mixed resin with glass fiber reinforcement, fillers, catalysts, and pigment.

2. Cutting & Weighing: SMC sheets are cut into the required size and weighed carefully to match the mold cavity volume.

3. Mold Preparation: Steel molds (upper and lower) are cleaned and coated with a mold release agent.

4. Hot Press Molding: The SMC material is placed inside the mold with an additional layer of fiberglass cloth and the temperature is raised to around 130–150°C for few minutes.

5. Demolding: After curing, the panel is removed from the mold.

6. Surface Finishing: Some panels are sanded or polished for a smoother finish.

7. Drilling and Edge Treatment: Drill holes for bolts, connectors, and flanges. (Korean FRP (SMC) water tank panels are designed with all four sides at a 90-degree right angle. This square-edge structure allows for precise alignment and tight sealing between adjacent panels during assembly)

8. Quality Inspection: Dimensional checks (length, width, thickness) and Visual inspection (cracks, bubbles, finish) and Mechanical tests (flexural strength, water absorption, impact resistance).

9. Packing and Storage: Panels are stacked and packed using foam or cardboard separators.

GRP panel water tank height matches the corrresponding panel weight

Higher Tanks Require Stronger Panels: As the tank height increases, the water pressure at the bottom increases. To withstand this pressure, thicker and heavier panels are used at the lower levels.

| Height | Bottom panel | Side one | Side two | Side three | Side four | Side five | Roof |

|---|---|---|---|---|---|---|---|

| 1000 mm | 15 kg | 12.5 kg | 10.5 kg | ||||

| 1500 mm | 16 kg | 15 kg | 9.5 kg

(1×0.5 m half panel) |

10.5 kg | |||

| 2000 mm | 17.5 kg | 15 kg | 12.5 kg | 10.5 kg | |||

| 2500 mm | 19 kg | 16 kg | 15 kg | 10.5 kg

(1×0.5 m half panel) |

10.5 kg | ||

| 3000 mm | 21.5 kg | 18 kg | 15 kg | 12.5 kg | 10.5 kg | ||

| 3500 mm | 23 kg | 21 kg | 18 kg | 15 kg |

10.5 kg (1×0.5 m half panel) |

10.5 kg | |

| 4000 mm | 25 kg | 24 kg | 18 kg | 15 kg | 12.5 kg | 10.5 kg | |

| 4500 mm | 29 kg | 27 kg | 23 kg |

12.5 kg (1×0.5 m half panel) |

15 kg | 10.5 kg | |

| 5000 mm | 29 kg | 27 kg | 23 kg | 18 kg | 15 kg | 12.5 kg | 10.5 kg |

Korea GRP panel performance

| Characteristics | GRP panel performance | Accepted criteria |

|---|---|---|

| Tensile Strength (MN/m²) | > 103 | >70 (min) |

| Bending Strength (MN/m²) | > 171 | > 100 (min) |

| Elastic Modulus in Bend (MN/m²) | > 12260 | > 6000 (min) |

| Glass Content (%) | > 40 | > 25 (min) |

| Barcol Hardness | 57 | >30 (min) |

| Water Absorption (%) | 0.1 | 0.5 (max) |

WRAS approved for Korea GRP water tank

Prevention of Water Contamination

Ensures that the water tank materials do not leach harmful substances into the stored water.

Prevents bacterial growth and maintains water hygiene, especially for potable (drinking) water storage.

Material Safety Compliance

Verifies that the tank is made from materials that meet UK safety standards.

Checks that coatings, linings, and seals do not introduce toxins into the water.

Backflow Prevention

Ensures the tank is designed to prevent backflow, which could lead to contamination of the public water supply.

Durability and Performance Assurance

Tests structural integrity to confirm that the tank can withstand pressure and environmental factors.

Ensures resistance to corrosion, UV exposure, and chemical degradation.

Regulatory Compliance for Legal Use

Many UK water authorities require WRAS certification for tanks used in public or commercial settings.

Helps manufacturers, suppliers, and installers comply with local water regulations, reducing legal risks.

What Huili Can do for your water tank solution?

Korea GRP Panel Water Tank Showing

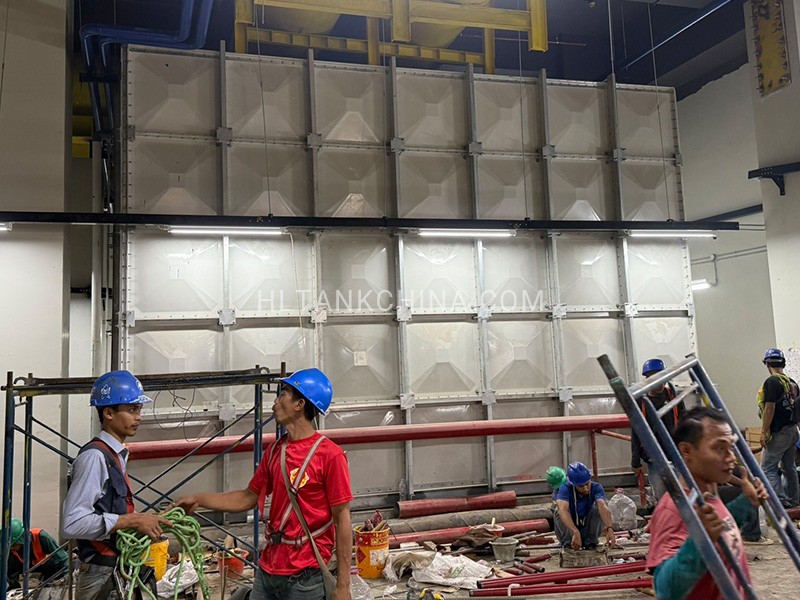

Showcasing 12-Turning Korea GRP Water Tank – Complex Custom Design for Singapore Project

This project features a uniquely complex 12-turning Korea GRP sectional water tank, custom-designed and installed by Huili for a facility in Singapore. The intricate layout required advanced engineering solutions to navigate space constraints while maintaining full functionality and structural integrity. This case showcases Huili’s expertise in delivering highly customized Korea-type GRP water tanks for challenging environments.

If you are interested in Korea-type GRP water tank also,just drop me email [email protected] or text Whatsapp:+8618505343912

Showcasing Huili’s Capability in Large and Tall Korea GRP Panel Sectional Water Tanks

Huili is not only experienced in designing and installing complex multi-turning water tanks like above Singapore project, but also in delivering large-scale and tall tanks. The following two projects feature Korea GRP panel sectional water tanks with capacities over 1000 cubic meters and a height of 5 meters.

Indonesia Korea panel GRP water tank 20x18x3m

Indonesia project 14(7+7)x7x5m (With partition)

Traditional GRP Panel water tank (National Standard 12S101)(Optional).

We make two types of GRP water tanks, one is above Korea GRP water tank(SS245 standard), one is below traditional GRP water tank (National Standard 12S101).

Below projects are our national standard GRP water tanks.

If you are interested in national standard GRP water tank also,just drop me email [email protected] or text Whatsapp:+8618505343912

Related Water Tank Products

Stay In Touch With Us