What is HDG Water Tank?

HDG water tank is the short of Hot Dip Galvanized water tank,with 90 μm thick surface zinc coating of Q235 Pressed Steel. Zinc coating can help to prevent rust and corrosion over at least 10 years. HDG water tanks have the most panels types including 1000 x 1000 mm,1000 x 500 mm,500 x 500 mm,1220 x 1220 mm.So HDG water tanks are more flexible and high cost-effective.Meanwhile,the strong steel structure and zinc coating protection has made it available to be used as underground water tank.

TECHNICAL DATA

PANELS

●MATERIAL

1. Q235B raw material complying China GB/T 700-2006 standard.

2. Surface zinc layer 70μm thickness complying GB/T19001-2008 standard.

3. Surface treatment optional: Enamel coating.

●SIZE & WEIGHT

1. The size of steel panels are produced by standard with 1.22*1.22 m,1*1 m, 1*0.5 m and 0.5*0.5 m.

2. The panel thickness is depends on tank height.

3. The maximum height available is 5 meters (Need add external reinforcement of I-beam for 5 m height).

●WATER TANK HEIGHT MATCHES PANEL THICKNESS.

| Height | Bottom Board | Side 1 | Side 2 | Side 3 | Side 4 | Side 5 | Top board |

|---|---|---|---|---|---|---|---|

| 1000 mm | 3 mm | 3 mm | 2 mm | ||||

| 1500 mm | 3 mm | 3 mm | 3 mm | 2 mm | |||

| 2000 mm | 3 mm | 3 mm | 3 mm | 2 mm | |||

| 2500 mm | 4 mm | 4 mm | 3 mm | 3 mm | 2 mm | ||

| 3000 mm | 4 mm | 4 mm | 3 mm | 3 mm | 2 mm | ||

| 3500 mm | 4 mm | 4 mm | 3 mm | 3 mm | 2.5 mm | 2 mm | |

| 4000 mm | 5 mm | 5 mm | 4 mm | 3 mm | 2.5 mm | 2 mm | |

| 4500 mm | 5 mm | 5 mm | 5 mm | 4 mm | 3 mm | 2.5 mm | 2 mm |

| 5000 mm | 5 mm | 5 mm | 5 mm | 4 mm | 3 mm | 2.5 mm | 2 mm |

●WEIGHT/EACH PANEL

| Item | 2 mm | 2.5 mm | 3 mm | 4 mm | 5 mm |

|---|---|---|---|---|---|

| 500 x 500 mm | 5.3 kg | 6.9 kg | 8 kg | 11 kg | 13.9 kg |

| 500 x 1000 mm | 9.5 kg | 12.5 kg | 14.6 kg | 19.9 kg | 25.2 kg |

| 1000 x 1000 mm | 17.4 kg | 22.7 kg | 26.6 kg | 36.2 kg | 46 kg |

| 1220 x 1220 mm | # | 33.6 kg | 39.3 kg | 53.7 kg | 68 kg |

●PHYSICAL PROPERTIES

| Physical properties | Standard requirement | Result |

|---|---|---|

| Tensile strength | ≥350 MPa | 509 MPa |

| Yield strength | ≥220 MPa | 414 MPa |

| Elongation | ≥23% | 24% |

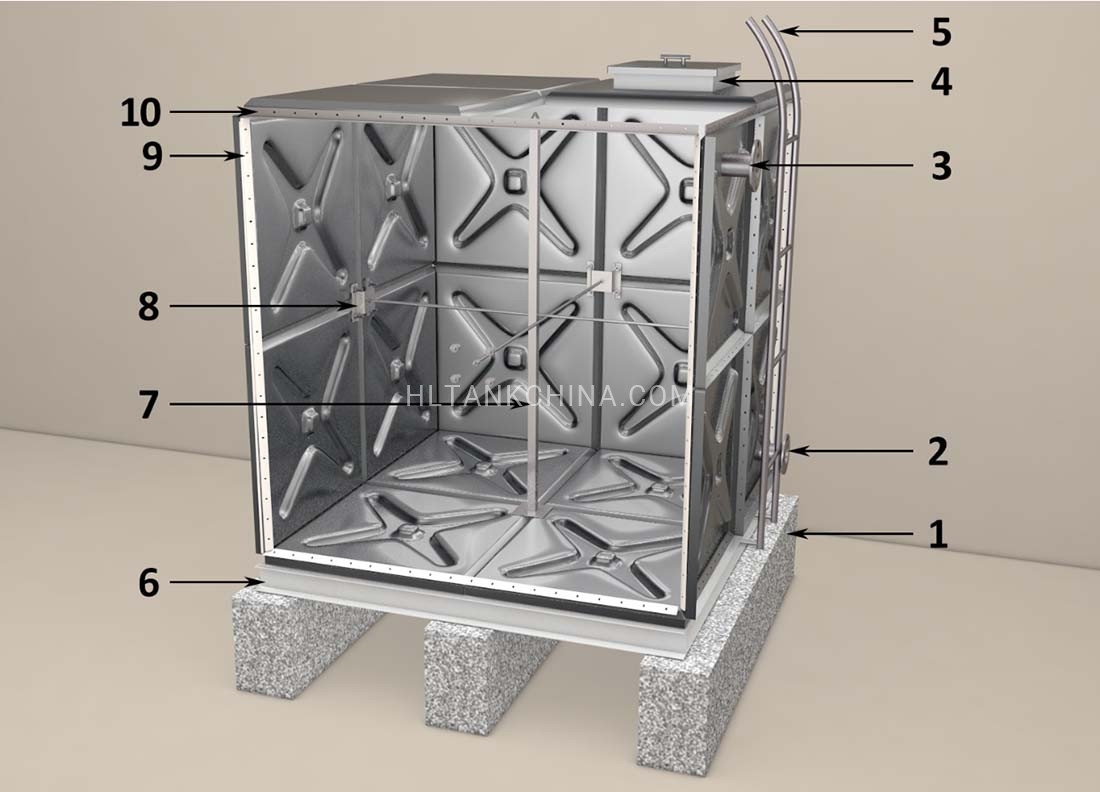

ACCESSORIES

1. Concrete beam 2. Outlet flange 3. Inlet flange 4. Manhole 5. External ladder 6. C-channel 7. Vertical support

8. Tie rod plate 9. Sealing rubber 10. Top angle bar

●BOLTS & NUTS—— 1. Hot dipped galvanized

●SKID BASE —— 1.Hot dipped galvanized 2.Painting

●INTERNAL STRUCTURE—— 1. Hot dipped galvanized

●FLANGES—— 1. Hot dipped galvanized 2. PVC

●SEALING RUBBER—— 1. Food grade white color EPDM 2. Silicon

●WATER INDICATOR—— 1. Glass with brass valve 2. Float type

DESCRIPTION

1. Hot dip galvanized water tank consists of four types of panels which can customize capacity according to local area and space.

2. The water tank height is usually set within 4 meters,we have set the water tank height up to 6 meters with my engineer good design.

3. Hot dip galvanized water tank structure is strong which can be used in underground and above ground used for storing firefighting,domestic water.

4. Hot dip galvanized water tank warranty time is 18 months since shipped out factory or 12 months since installation,based on closed one.

5. Hot dip galvanized water tank mainly used in hospital,residence,campus,supermarket,airport,football ground,irrigation,and somewhere lacking water.

FEATURES

1. All hot dip galvanized materials and national standard.

2. Panels consist of 1220 x 1220 mm,1000 x 1000 mm,1000 x 500 mm,500 x 500 mm four types.

3. Water tank uses the different panel thickness according to above table.

4. U-steel is optional between hot dip galvanized and painting according to customer’s requirement.

5. It could be used overhead water tank or insulated water tank.

APPLICATION

What are water tanks widely used for?

2. Agricultural Irrigation Tanks

3. Septic Tanks and Sewage Tanks

4. Distillation and Process Tanks

5. Fire Reserve Storage Tanks,Swimming Pool Balance Tanks

6. Hot Water Storage Tanks and Chemical Substance Storage Tanks

7. Rain Water Harvesting Tanks,Well Water Tanks,Sea Water Tanks

8. Reverse-Osmosis Water Tanks(water with high or low conductivity)

9. Industrial Process Tanks,Chiller Water Tanks,Cooling Tower Water Tanks

DESIGN

PACKING

With over 20 years factory manufacturing experience and five years of export experience,we designed and evolved packing a lot for delivery safety and most cost effective.

Connect to your next successful water tank project !

INSTALLATION

Technical support

ADVANTAGES

ANTI-CORROSION

The thickness of zinc layer can be up to 70μm, have superior anti-corrosion capability.

RELIABLE QUALITY

Our panel comply the standard of Singapore PSB, SGS, China QSB, etc. The life-span can be over 1/4 century.

DIMENSION FLEXIBILITY

The size of panel can be 1.22*1.22 m, 1*1 m, 1*0.5 m and 0.5*0.5 m, which can assemble kinds of volume from 0.125 m³ to 5000 m³. That’s extremely convenient to select for you.

CONVENIENT INSTALLATION

Factory precast panel is easy to assemble and disassemble, the construction drawing, installation video, and a series of complete installation plan will be provided.

DURABLE

Using the 1000 T hydraulic press integrated molding, no welding seam at panel corners.

BURY UNDERGROUND

All the HUILI steel material water tank can be bury underground, the thickness of inner structure and panels are thicker than normal tank.

DOWNLOAD

PRODUCTION SCOPE

As over 20 years of water tank manufacturer,we have established 4 production lines separately for GRP modular water tank,HDG water tank,Stainless steel water tank,GSC underground water tank,which include 58 skilled engineers, 8 sets of molding pressure machines.

Except above water tank series,we could process and customize other SMC products such as electric pole protection cases,farm planting SMC series.

National standard (12S101) pressed steel sectional rectangular water tank showing

The Tanzania Coca-Cola project features a 40m × 10m × 5m (H) National Standard HDG sectional steel water tank, offering a total storage capacity of approximately 2,000 cubic meters.

The Qatar project includes a 22m (11+11) × 5m × 5m (H) (With partition) National Standard HDG water tank, also designed with a height of 5 meters to meet the specific storage and operational requirements of the site.

Both projects highlight Huili’s capability in handling tanks with a height of 5 meters (Our maximum height is 7 meters pressed steel water tank located in Singapore), which requires precise structural design, panel reinforcement, and base support planning to ensure long-term stability and operational safety. Each tank was engineered, prefabricated, and installed according to its unique site conditions and project goals.

If you have any water tank inquiries,just drop me email [email protected] or text Whatsapp:+8618505343912.

Tanzania Coca-Cola project 40x10x5m (H)

British standard pressed steel sectional rectangular water tank showing (Optional)

Huili is capable of designing and manufacturing hot-dip galvanized (HDG) sectional steel water tanks in accordance with both the National Standard (12S101) and British Standard (BS 1564:1975) (Initially from Braithwaite pressed steel panel sectional water tanks), depending on the unique requirements of each project.

While Huili has delivered many large-scale tanks under the National Standard, we also have extensive experience with British Standard tanks (two different patterns of panels for your reference):

One such project, located in Tanzania, was built to British Standard (BS 1564:1975) and features dimensions of 25.62 × 24.4 × 4.88 meters (H). This tank offers a storage capacity exceeding 3,000 cubic meters, demonstrating our ability to deliver high-volume, structurally sound solutions in demanding environments.

Another British Standard tank was delivered for a municipal project in Lesotho. This tank measures 17.08 × 17.08 × 3.66 meters (H) and was designed to support stable and efficient water supply for local government needs.

If you have any water tank inquiries,just drop me email [email protected] or text Whatsapp:+8618505343912.

BS1564 Lesotho Municipal Project 17.08 x17.08×3.66m(H) (Pattern-two)

Elevated Steel Water Tank vs Ground Water Tank

According to the installation position, HDG (Hot-Dip Galvanized) water tanks can be categorized into elevated (or overhead) water tanks and ground (or on-ground) water tanks. Here’s a detailed description of each type:

Elevated HDG Water Tank (Overhead Water Tank)

Installation Position: Installed at a height, usually on top of a tower, steel support structure, or building rooftop.

Purpose:

Provides gravity-fed water supply, eliminating the need for continuous pumping.

Ensures stable water pressure for residential, commercial, and industrial applications.

Commonly used in municipal water supply systems, high-rise buildings, agricultural irrigation, and firefighting systems.

Structural Features:

Requires strong supporting structures (concrete or steel towers) to bear the weight of the filled tank.

The tank is often designed with corrosion-resistant coatings to withstand outdoor exposure.

Can be constructed in modular panel form for easy transportation and assembly.

Advantages:

Energy-efficient: Uses gravity instead of relying on pumps.

Reliable water supply even during power outages.

Disadvantages:

Higher installation cost due to the need for a support structure.

Requires structural reinforcement for earthquake and wind resistance.

Ground HDG Water Tank (On-Ground Water Tank)

Installation Position: Installed directly on the ground or on a concrete base/foundation.

Purpose:

Used for water storage in factories, fire protection, agriculture, and residential areas.

Serves as a backup water supply in case of shortages or emergencies.

Structural Features:

Typically modular and assembled using galvanized steel panels.

Often equipped with inlet, outlet, overflow, and drainage pipes for efficient water management.

Can be customized in various sizes and shapes to fit available space.

Advantages:

Easier installation with lower structural requirements.

Scalable: Can be expanded by adding more panels.

Disadvantages:

Needs a pump to distribute water at higher pressure.

Takes up more ground space, which may not be ideal in urban areas.

Comparison Summary

| Feature | Elevated HDG Water Tank | Ground HDG Water Tank |

|---|---|---|

| Installation | On a tower/building | On a concrete foundation |

| Water Supply | Gravity-fed, no pump needed | Needs a pump for distribution |

| Cost | Higher (structure required) | Lower |

| Usage | Municipal, firefighting, irrigation | Industrial, backup storage, fire safety |

| Maintenance | More challenging due to height | Easier access for maintenance |

Elevated HDG water tank in Botswana

Elevated HDG water tank in Nigeria

Related Water Tank Products

Stay In Touch With Us