What is Corrugated Steel Water Tank?

The circular corrugated sectional metal steel water tank has two types according to raw material.

One is galvanized steel water tank (Z275 and G90 standard:275 g/m²).

One is zincalume steel water tank.(We take ZMA275 standard with its higher aluminium content, typically has same strength and corrosion resistance compared to Bluescope zinc alumnimium)

Above two water tanks are called water silos which is a cheaper option for water storing.Due to less metal parts with same capacity, it has the advantage of less price and easier installation.The tank is assembled by two main parts combined corrugated sheet for wall and food-grade tarpaulin or PVC inside for loading water.

The cylindrical corrugated metal steel water tank has a lifespan over 20 years which is an more economical, efficient and safer large water storage tank. It is suitable for all kinds of irrigation and domestic water and potable water tank, such as greenhouse irrigation, greenhouse rainwater collecting, temporary water storage at construction sites etc.

Zinc-Aluminum Water Tank VS Corrugated Galvanized Steel (CGS) Water Tank

Advantages of Corrugated Steel Water Tank

1. Durability & Strength – Corrugated steel tanks are highly durable, with strong resistance to external impacts, harsh weather conditions, and seismic activities.

2. Corrosion Resistance – Galvanized or coated steel options provide excellent resistance against rust and corrosion, extending the tank’s lifespan.

3. Large Storage Capacity – Available in various sizes, these tanks can store large volumes of water, making them ideal for industrial and agricultural applications.

4. Modular & Easy Installation – Pre-fabricated components allow for quick and cost-effective assembly on-site, reducing installation time and labor costs.

5. Cost-Effective – Compared to concrete or fiberglass tanks, corrugated steel tanks provide a long lifespan with lower maintenance costs.

6. Eco-Friendly – Many corrugated steel tanks are made from recyclable materials, making them a sustainable choice.

7. Customizable – They can be tailored to specific needs with liners, coatings, and additional features such as roofs or insulation.

8. Seismic Stability – Corrugated steel water tanks are designed to withstand seismic forces, making them an ideal choice for regions prone to earthquakes. Their flexibility and structural integrity allow them to absorb and dissipate energy, minimizing the risk of damage during seismic events.

Corrugated Steel Water Tank Type

Steel Dome Roof Water Tank (Two types of roof designs):

Designed with a fully enclosed steel dome roof to prevent contaminants from entering. Ideal for potable water storage, agricultural irrigation, and industrial applications.

Open Top Water Tank:

Features an open-top design, making it suitable for applications that require frequent water access, such as aquaculture, fish farming, or rainwater collection.

PVC Roof Water Tank:

Equipped with a PVC-covered roof to protect stored water from dust and debris. Commonly used for agricultural, firefighting, and industrial water storage.

Open Top Water Tank

PVC Roof Water Tank

Water Tank Capacities based on Diameter and Height

The table presents data on the capacity of cylindrical water tanks based on their diameter and height. By analyzing this information, we can determine how tank dimensions influence storage volume and help in selecting the right tank for various applications.

| Diameter

(m) |

Height

(m) |

Capacity

(m3) |

Diameter

(m) |

Height

(m) |

Capacity

(m3) |

Diameter

(m) |

Height

(m) |

Capacity

(m3) |

Diameter

(m) |

Height

(m) |

Capacity (m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 0.88 | 6 | 4 | 0.88 | 11 | 5 | 0.88 | 17 | 6 | 0.88 | 25 |

| 3 | 1.18 | 8 | 4 | 1.18 | 15 | 5 | 1.18 | 23 | 6 | 1.18 | 33 |

| 3 | 2.3 | 16 | 4 | 2.3 | 29 | 5 | 2.3 | 45 | 6 | 2.3 | 65 |

| 3 | 3.41 | 24 | 4 | 3.41 | 43 | 5 | 3.41 | 67 | 6 | 3.41 | 96 |

| 7 | 0.88 | 34 | 8 | 0.88 | 44 | 9 | 0.88 | 56 | 10 | 0.88 | 69 |

| 7 | 1.18 | 45 | 8 | 1.18 | 59 | 9 | 1.18 | 75 | 10 | 1.18 | 93 |

| 7 | 2.3 | 88 | 8 | 2.3 | 116 | 9 | 2.3 | 146 | 10 | 2.3 | 181 |

| 7 | 3.41 | 131 | 8 | 3.41 | 171 | 9 | 3.41 | 217 | 10 | 3.41 | 268 |

| 11 | 0.88 | 84 | 12 | 0.88 | 99 | 13 | 0.88 | 117 | 14 | 0.88 | 135 |

| 11 | 1.18 | 112 | 12 | 1.18 | 133 | 13 | 1.18 | 157 | 14 | 1.18 | 182 |

| 11 | 2.3 | 218 | 12 | 2.3 | 260 | 13 | 2.3 | 305 | 14 | 2.3 | 354 |

| 11 | 3.41 | 324 | 12 | 3.41 | 385 | 13 | 3.41 | 452 | 14 | 3.41 | 525 |

| 15 | 0.88 | 155 | 16 | 0.88 | 177 | 17 | 0.88 | 200 | 18 | 0.88 | 224 |

| 15 | 1.18 | 208 | 16 | 1.18 | 237 | 17 | 1.18 | 268 | 18 | 1.18 | 300 |

| 15 | 2.3 | 406 | 16 | 2.3 | 462 | 17 | 2.3 | 522 | 18 | 2.3 | 585 |

| 15 | 3.41 | 602 | 16 | 3.41 | 685 | 17 | 3.41 | 774 | 18 | 3.41 | 867 |

| 19 | 0.88 | 249 | 20 | 0.88 | 276 | 21 | 0.88 | 305 | 22 | 0.88 | 334 |

| 19 | 1.18 | 334 | 20 | 1.18 | 371 | 21 | 1.18 | 408 | 22 | 1.18 | 448 |

| 19 | 2.3 | 652 | 20 | 2.3 | 722 | 21 | 2.3 | 796 | 22 | 2.3 | 874 |

| 19 | 3.41 | 966 | 20 | 3.41 | 1071 | 21 | 3.41 | 1180 | 22 | 3.41 | 1296 |

| 23 | 0.88 | 365 | 24 | 0.88 | 398 | 25 | 0.88 | 432 | 26 | 0.88 | 467 |

| 23 | 1.18 | 490 | 24 | 2.3 | 534 | 25 | 1.18 | 579 | 26 | 1.18 | 626 |

| 23 | 2.3 | 955 | 24 | 3.41 | 1040 | 25 | 2.3 | 1128 | 26 | 2.3 | 1221 |

| 23 | 3.41 | 1416 | 24 | / | / | 25 | / | / | 26 | / | / |

| 27 | 0.88 | 504 | 28 | 0.88 | 542 | 29 | 0.88 | 581 | 30 | 0.88 | 622 |

| 27 | 1.18 | 675 | 28 | 1.18 | 726 | 29 | 1.18 | 779 | 30 | 1.18 | 834 |

| 27 | 2.3 | 1316 | 28 | 2.3 | 1416 | 29 | 2.3 | 1518 | 30 | 2.3 | 1625 |

(Both the diameter and height are custom-supported,see below 4.52m high customized water tank)

Professional Site Installation Guidelines for 4.52m High Corrugated Steel Water Tank

For every installation, we provide a detailed drawing, installation manual, and instructional video to guide you through the assembly process. With these comprehensive documents, customers can efficiently and accurately install the water tank with ease.

For 4.52m high water tanks, we incorporate external reinforcement to enhance structural strength and stability, ensuring durability under various conditions. However, for tanks 3.41m and below, external reinforcement is not required, as the structure remains robust without additional support. This design approach optimizes both strength and cost-efficiency while maintaining high performance.

Indonesia customized 13.5 x 4.52m high corrugated steel water tank internal installation

Indonesia customized 13.5 x 4.52m high corrugated steel water tank external installation

Corrugated Steel Water Tank Application

1. Agriculture & Irrigation – Used for storing rainwater, groundwater, or irrigation water for farms, livestock, and crop production.

2. Municipal Water Supply – Often used in rural or urban areas for potable water storage.

3. Fire Protection – Essential for fire suppression systems in residential, commercial, and industrial areas.

4. Rainwater Harvesting – Ideal for collecting and storing rainwater for domestic and commercial use.

5. Industrial Water Storage – Used in manufacturing plants, mining, and power plants to store process water, cooling water, or wastewater.

6. Emergency Water Supply – Critical in disaster preparedness, providing water reserves for emergency situations.

7. Potable Water Storage – With appropriate linings and coatings, these tanks can store drinking water safely for residential and commercial applications.

8. Fishing Tanks – Ideal for creating controlled environments for aquaculture. Corrugated steel water tanks are used in fish farming for breeding, raising, and maintaining aquatic life in a stable water environment.

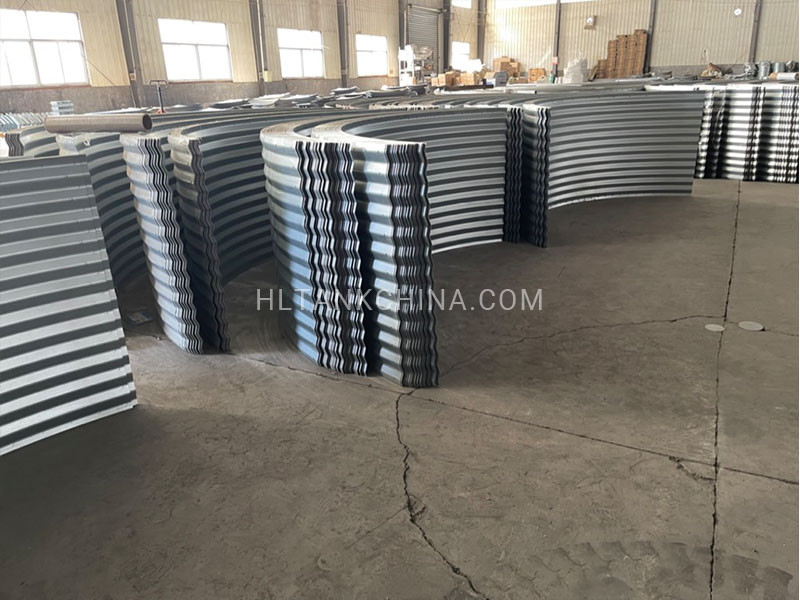

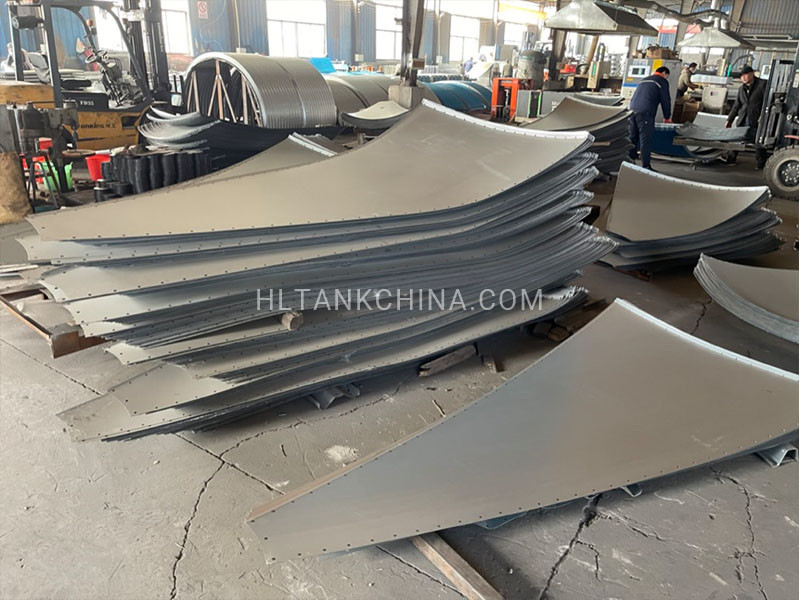

Factory Tour

Our process begins with high-grade galvanized or zinc aluminum steel sheets. These sheets are sourced from trusted and listed suppliers and undergo rigorous quality checks to ensure durability and corrosion resistance.

Corrugated steel water tank project cases

Looking for a durable, cost-effective, and easy-to-install water storage solution? Our corrugated steel water tanks are designed for various applications, including agriculture, industry, firefighting, and drinking water storage. We provide customized designs and detailed drawings to meet your specific needs.

If you have any water tank inquiries, just drop me email [email protected] or text Whatsapp: +8618505343912

Huili – Your Trusted Partner for Corrugated Steel Water Tanks

At Huili, we are committed to delivering high-quality, durable, and customized corrugated steel water tanks for various applications. Our expert team ensures that every tank is designed for maximum strength, longevity, and efficiency.

Why Choose Huili Water Tanks?

1.Easy Installation – We provide a detailed installation video and drawing to ensure a smooth setup.

2.Fully Customizable – Our team tailors each tank to match your specific capacity and site requirements.

3.Patented Strength – Huili’s innovative design and engineering make our tanks stronger, safer, and more practical.

Related Water Tank Products

Stay In Touch With Us