BS HDG Water Tank Features?

High-Quality Galvanized Steel Construction

Made from hot-dip galvanized steel panels( Q235B) that provide superior corrosion resistance.

Complies with BS EN ISO 1461, ensuring a thick and uniform zinc coating.

Excellent Corrosion & Weather Resistance

Zinc coating protects the steel from oxidation and rust.

Suitable for outdoor and harsh environmental conditions, including industrial and coastal areas.

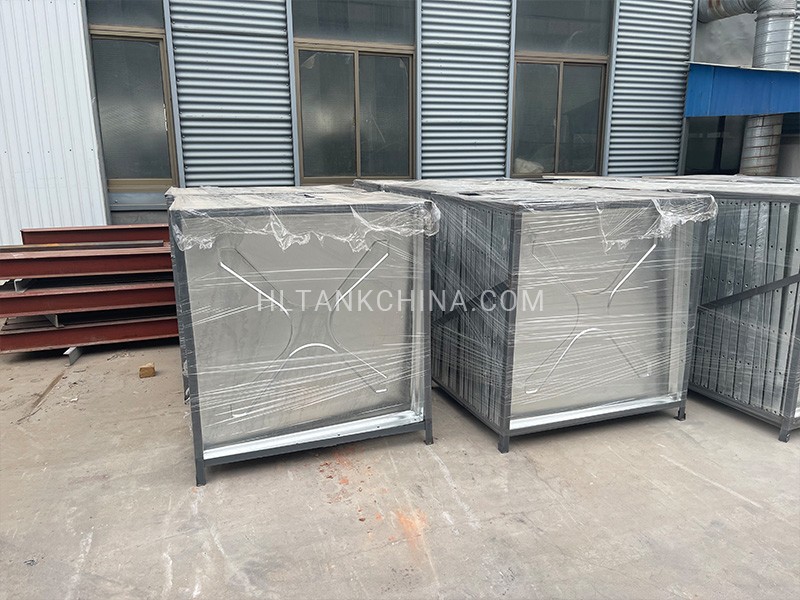

Modular Design for Easy Installation

Available in bolted or welded panel configurations for flexible assembly.

Customizable in various sizes to meet different water storage capacities.

Compliance with British Standards

Designed according to BS 1564:1975 (for rectangular and sectional steel tanks).

Coating process complies with BS EN ISO 1461 for hot-dip galvanization.

Leak-Proof & Durable Structure

Precision bolted connections with rubber gaskets prevent leaks.

Reinforced structure ensures resistance to hydrostatic pressure and seismic conditions.

British Standard (BS 1564:1975) Hot Dip Galvanized (HDG) Water Tank Made in China

We specialize in designing and manufacturing hot-dip galvanized (HDG) steel water tanks for Malaysia that comply with British Standards (Initially from Braithwaite pressed steel panel sectional water tanks). Our focus on OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) means that we not only customize production according to clients’ brands and specifications (OEM) but also provide complete product design and development solutions (ODM).

OEM (Original Equipment Manufacturing)

- Clients provide designs, specifications, and branding requirements, and you handle the manufacturing process.

- Ensures compliance with British Standards such as BS 1564, BS 7491, or the latest BS EN 13280.

- Suitable for companies with specific market needs, such as government projects, industrial water supply, and construction applications.

ODM (Original Design Manufacturing)

- We are not just a manufacturer but also provide product design and technical improvements.

- This may include optimizing modular assembly structures, enhancing galvanization processes, and improving corrosion resistance.

- We offer complete water tank solutions, including design, manufacturing, and quality control.

Advantages of Malaysia-Based Design

- Optimized for local climate and market needs, such as enhanced heat and weather resistance.

- Mature production processes with cost competitiveness, meeting international export requirements.

- A stable supply chain that caters to Southeast Asia, the Middle East, and other global markets.

British Standard 1220x1220mm panel

Foam sealing tape

Stay angle

External ladder

C-channel skid base

Bracket / Cleat

Horizontal support (Truss)

Adjustable support base(optional)

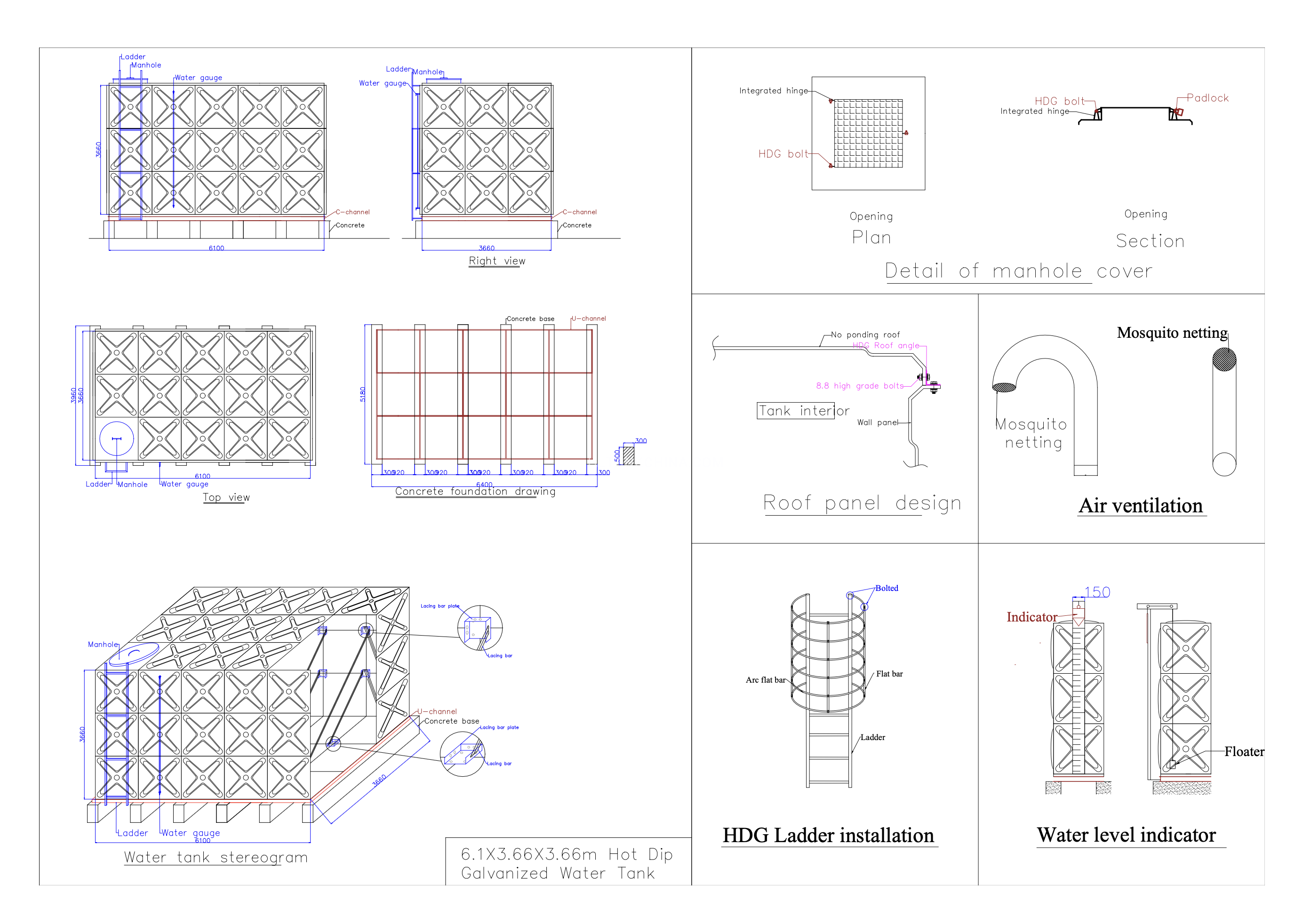

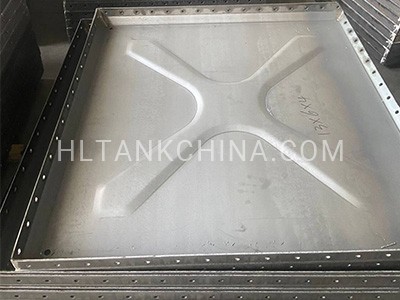

1. British Standard 1220x1220mm Panel

Function: The main structural unit of the water tank, complying with BS 1564, BS 7491, or BS EN 13280 British standards.

Material: Hot-dip galvanized steel (HDG), stainless steel (SS304/SS316), depending on requirements.

Features: Corrosion-resistant, high-strength, modular design, easy to install and expand.

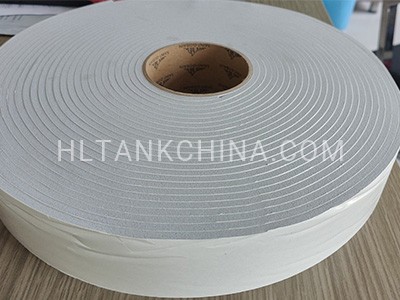

2. Foam Sealing Tape

Function: Used for sealing between water tank panels to prevent water leakage and provide cushioning.

Material: Usually made of EPDM, PE, PU, or silicone foam, offering waterproof, weather-resistant, UV-resistant, and high-temperature-resistant properties.

3. Stay Angle

Function: Used inside or outside the water tank to reinforce structural stability and prevent deformation due to water pressure.

Material: Galvanized steel or stainless steel, providing corrosion resistance.

Features: Offers additional support.

4. External Ladder

Function: Provides a safe access route for water tank maintenance and inspection.

Material: Galvanized steel, stainless steel, or aluminum, with optional anti-slip design.

Features: Customizable in different heights, compliant with safety standards like EN ISO 14122-4.

5. C-Channel Skid Base

Function: Acts as the foundation support structure for the water tank, enhancing stability and providing ground clearance to prevent bottom corrosion.

Material: Hot-dip galvanized steel or stainless steel.

Features: Increases load-bearing capacity and ensures stability on various surfaces.

6. Bracket

Function: Provides structural support and reinforcement for various components of the water tank.

Material: Galvanized steel or stainless steel.

Features: Enhances durability and load-bearing capacity, ensuring the tank remains structurally sound.

7. Horizontal Support (Truss)

Function: Provides horizontal and vertical reinforcement to maintain the structural integrity of the water tank, distributing loads evenly.

Material: Galvanized steel or stainless steel, ensuring high strength and durability.

Application: Used to prevent deformation due to water pressure or external forces.

8. Adjustable Support Base (Optional)

Function: Provides adjustable support for the water tank, accommodating uneven ground to ensure level installation.

Material: Galvanized steel or stainless steel, equipped with adjustable bolts.

Features: Suitable for irregular terrains, allowing for height adjustments as needed.

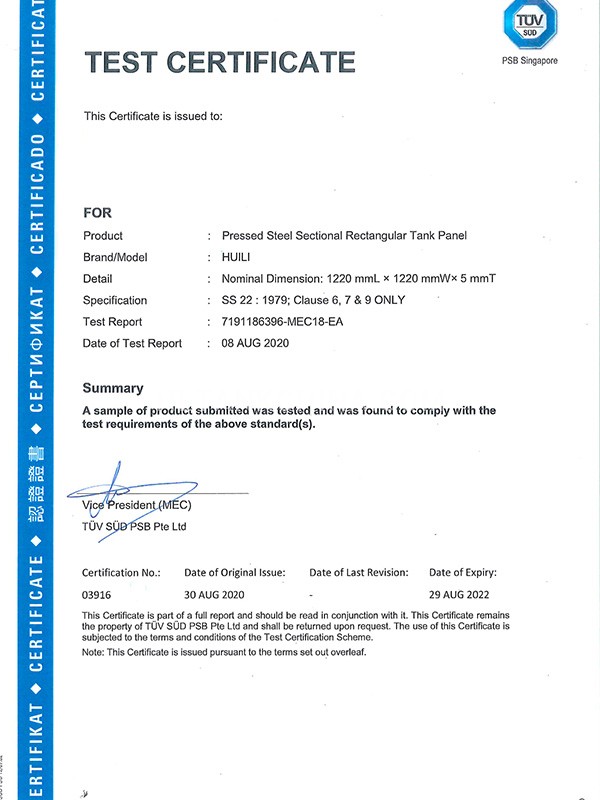

PSB ( Singapore Standard) approved for BS HDG water tank

Compliance with Singapore’s Water Standards

Water tanks must meet PUB requirements for non-potable water storage, such as firefighting, irrigation, and industrial water.

PSB-approved tanks ensure adherence to structural integrity and corrosion resistance standards.

Reference to British Standards (BS 1564 & BS EN 1461)

HDG water tanks are typically manufactured to BS 1564:1975 (for rectangular and sectional steel tanks).

The hot-dip galvanization process must comply with BS EN ISO 1461, ensuring adequate zinc coating thickness (typically 70-100 μm).

Material & Coating Requirements

Galvanized steel panels must have a uniform zinc coating to prevent corrosion.

Tanks should undergo corrosion resistance tests as part of PSB certification.

Leakage & Pressure Testing

Tanks are tested for structural stability under hydrostatic pressure.

Joints and gaskets must be water-tight to prevent leaks.

Application of PSB-Approved HDG Water Tanks in Singapore

Firefighting water storage in commercial and industrial buildings.

Rainwater harvesting and irrigation systems.

Cooling water tanks for HVAC systems.

Non-potable water storage in factories and power plants.

Thickness requirements for pressed steel sectional rectangular tanks according to BS 1564:1975

The thickness of pressed steel sectional rectangular water tanks under BS 1564:1975 depends on the tank height and the design requirements. The standard specifies different plate thicknesses for different tank panel sections to ensure structural integrity.

Here’s a general thickness matching for a rectangular sectional water tank according to BS 1564:1975:

| Tank Height (mm) | Panel required | Thickness(mm) |

|---|---|---|

| 1220 | Bottom, sides and ends. | 5 |

| 2440 | Bottom, sides and ends. | 5 |

| 3660 | Bottom, sides and ends. | 5 |

| 4880 | Bottom, sides and ends. | 6 |

| 4880 | Second, third and top tiers of sides and ends. | 6 |

What Huili Can do for your pressed steel panel water tank solution?

British standard pressed steel sectional rectangular water tank showing

Furthermore, we provide an alternative design of British Standard water tanks featuring a different panel pattern. Kindly refer to the image below:

Huili has experience in designing and manufacturing large-scale pressed steel sectional water tanks. The first project shown here, located in Tanzania, follows the British Standard (BS 1564:1975) and measures 25.62 × 24.4 × 4.88 meters (H), with a storage capacity of over 3,000 cubic meters.

Another British Standard tank was delivered for a municipal project in Lesotho. This tank measures 17.08 × 17.08 × 3.66 meters (H) and was designed to support stable and efficient water supply for local government needs.

For any water tank inquiries, feel free to contact us via email at [email protected] or reach us on WhatsApp at +8618505343912.

Tanzania British Standard 25.62×24.4×4.88mm (H) (Pattern-one)

British Standard HDG water tank inner design

BS1564 Lesotho Municipal Project 17.08 x17.08×3.66m(H) (Pattern-two)

British Standard HDG water tank inner design

National standard pressed steel sectional rectangular water tank showing (Optional)

Huili has the capability to design and manufacture hot-dip galvanized (HDG) sectional steel water tanks according to both British Standard (BS 1564:1975) and National Standard specifications (12S101), depending on the project needs.

As shown in above British Standard HDG water tank, we have successfully delivered large-scale tanks under National Standard (12S101):

The National Standard tank, supplied for the Coca-Cola facility in Tanzania, measures 40 × 10 × 5 meters, also offering significant water storage volume.

Elevated Steel Water Tank vs Ground Water Tank

According to the installation position, HDG (Hot-Dip Galvanized) water tanks can be categorized into elevated (or overhead) water tanks and ground (or on-ground) water tanks. Here’s a detailed description of each type:

Elevated HDG Water Tank (Overhead Water Tank)

Installation Position: Installed at a height, usually on top of a tower, steel support structure, or building rooftop.

Purpose:

Provides gravity-fed water supply, eliminating the need for continuous pumping.

Ensures stable water pressure for residential, commercial, and industrial applications.

Commonly used in municipal water supply systems, high-rise buildings, agricultural irrigation, and firefighting systems.

Structural Features:

Requires strong supporting structures (concrete or steel towers) to bear the weight of the filled tank.

The tank is often designed with corrosion-resistant coatings to withstand outdoor exposure.

Can be constructed in modular panel form for easy transportation and assembly.

Advantages:

Energy-efficient: Uses gravity instead of relying on pumps.

Reliable water supply even during power outages.

Disadvantages:

Higher installation cost due to the need for a support structure.

Requires structural reinforcement for earthquake and wind resistance.

Ground HDG Water Tank (On-Ground Water Tank)

Installation Position: Installed directly on the ground or on a concrete base/foundation.

Purpose:

Used for water storage in factories, fire protection, agriculture, and residential areas.

Serves as a backup water supply in case of shortages or emergencies.

Structural Features:

Typically modular and assembled using galvanized steel panels.

Often equipped with inlet, outlet, overflow, and drainage pipes for efficient water management.

Can be customized in various sizes and shapes to fit available space.

Advantages:

Easier installation with lower structural requirements.

Scalable: Can be expanded by adding more panels.

Disadvantages:

Needs a pump to distribute water at higher pressure.

Takes up more ground space, which may not be ideal in urban areas.

Comparison Summary

| Feature | Elevated HDG Water Tank | Ground HDG Water Tank |

|---|---|---|

| Installation | On a tower/building | On a concrete foundation |

| Water Supply | Gravity-fed, no pump needed | Needs a pump for distribution |

| Cost | Higher (structure required) | Lower |

| Usage | Municipal, firefighting, irrigation | Industrial, backup storage, fire safety |

| Maintenance | More challenging due to height | Easier access for maintenance |

Elevated HDG water tank in Botswana

Elevated HDG water tank in Nigeria

Related Water Tank Products

Stay In Touch With Us