What is GRP ladder?

A GRP ladder is a type of industrial ladder made from fiberglass reinforced plastic,which is called FRP ladder or SMC ladder, a composite material consisting of fiberglass and resin. GRP ladders are widely used in corrosive and high-risk environments such as water treatment plants, chemical facilities, offshore platforms, and electrical substations.A GRP ladder is a type of industrial ladder made from glass reinforced plastic, a composite material consisting of fiberglass and resin. GRP ladders are widely used in corrosive and high-risk environments such as water treatment plants, chemical facilities, offshore platforms, and electrical substations.

GRP/FRP/SMC ladders are used for our water tanks.

As over 30 years of water tank manufacturer, our GRP /FRP/SMC ladders are widely used in various water tanks inlcuding GRP water tank,HDG water tank,corrugated steel water tank and Stainless steel water tank and Concrete water tank.

GRP/FRP/SMC Water Tank Ladder Features:

Corrosion Resistant:

Ideal for humid and chemically aggressive environments inside water storage systems.

Lightweight & High Strength:

Easy to install and handle without compromising structural safety.

Non-Conductive Material:

Provides electrical insulation for added safety in industrial environments.

Anti-Slip Surface:

Rungs are engineered with a textured surface to prevent slipping, even in wet conditions.

Maintenance-Free:

No painting or anti-rust treatment required, minimizing long-term maintenance cost.

Custom-Fit Design:

Length, width, and structure can be tailored to fit tank dimensions and customer requirements. Options include internal ladders for tank entry and external ladders with safety cages for rooftop access.

GRP ladder used for GRP water tank

GRP ladder used for concrete water tank

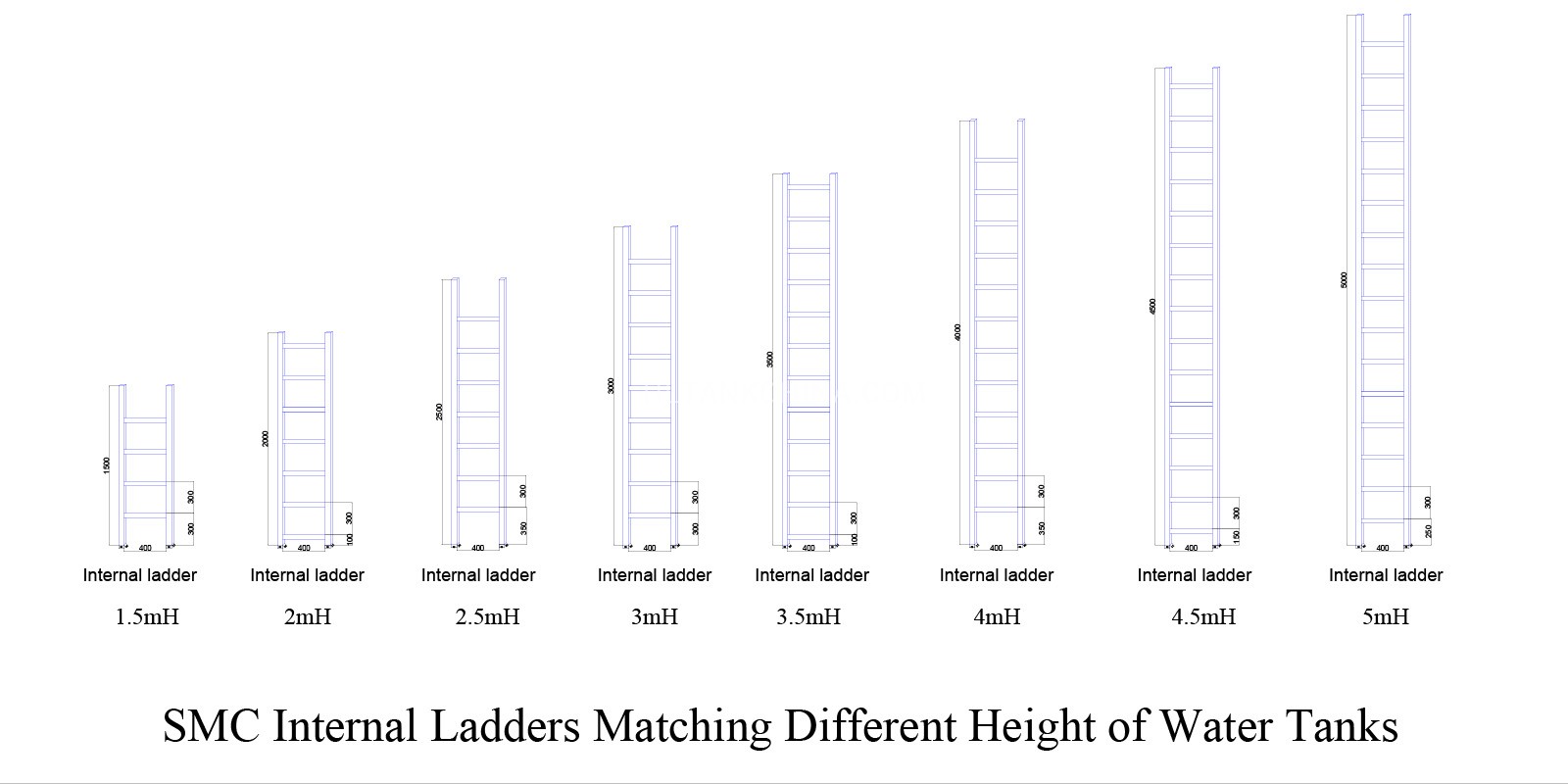

Below are the SMC/GRP/FRP fiberglass ladders for different heights of water tanks

The image displays SMC ( referring to our own brand Huili Water Tank ) internal ladders designed for water tanks of varying heights to ensure safe and convenient access. The following ladder models are listed, each corresponding to a specific tank height:

Beyond Water Tanks: Versatile Applications of GRP Ladders

GRP ladders (Glass Reinforced Plastic ladders), also known as fiberglass ladders, are widely used across various industries due to their excellent corrosion resistance, electrical insulation, high strength-to-weight ratio, and long service life. We customize the SMC ladders according to your requirements.Below are some of the most common application areas:

Industrial Sector

Chemical plants & refineries: Highly resistant to acids and alkalis, making them ideal for corrosive environments and a good alternative to metal ladders.

Wastewater treatment plants: Suitable for aeration tanks, sedimentation tanks, and other wet, corrosive conditions.

Power plants: Especially in substations and power distribution areas, their non-conductive nature enhances operational safety.

Construction & Infrastructure

Water tanks & inspection hatches: Commonly used inside or outside GRP/FRP water tanks for maintenance purposes.

Telecom towers & antenna structures: Lightweight and easy to install at height.

Bridges & underground tunnels: Durable and slip-resistant, providing reliable access.

Marine & Offshore Platforms

Ships & oil rigs: Saltwater and weather-resistant, with a long service lifespan in harsh marine environments.

Food & Pharmaceutical Industry

Food processing facilities: Non-corrosive and hygienic, ensuring no contamination.

Clean rooms in pharmaceutical plants: Non-conductive, bacteria-resistant, and easy to sanitize.

Electrical & Communication Sector

Substation maintenance & cable trenches: Electrically insulating to protect personnel.

Subways & utility tunnels: Easy to install, weather-resistant, and low maintenance.

Water & Environmental Engineering

Pump rooms, distribution chambers, and water treatment zones: Anti-corrosive and easy to maintain, even in humid environments.

SMC Custom Solutions — Tailored GRP/FRP Products from the Source

As a professional GRP/FRP water tank manufacturer, we go beyond simply assembling tanks—we produce our own SMC (Sheet Molding Compound) materials, allowing us to control quality from the source. This gives us the flexibility to customize SMC custom product bending strength, tensile strength, compressive strength, and more to meet the unique needs of each client

Customize SMC flberglass peroperties to meet your different requirements

One of the key advantages of using SMC-based fiberglass (FRP) products is the ability to fine-tune material properties during the manufacturing process. By adjusting the composition, structure, and processing of the fiberglass sheet, we can produce products with targeted mechanical and physical performance—perfectly aligned with your project’s demands

| Sample No. | Flexural Strength (MPa) | Tensile Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|

| 1 | 191.22 | 99.94 | 132.53 |

| 2 | 153.39 | 79.85 | 123.69 |

| 3 | 128.59 | 59.64 | 140.59 |

| Your custom SMC | …… | …… | …… |

Some SMC custom products showing

The image showcases a selection of custom SMC (Sheet Molding Compound) products manufactured using GRP (Glass Reinforced Plastic) or FRP (Fiber Reinforced Plastic) materials. The displayed products include GRP/FRP Box Section,GRP/FRP Angle Profile,GRP/FRP Pipes,GRP/FRP I-Beam.

These products highlight the versatility of GRP/FRP materials in creating custom, high-performance solutions for construction, infrastructure, and industrial uses.

GRP/FRP box section

GRP/FRP angle profile

GRP/FRP pipes

GRP/FRP I-Beam

Stay In Touch With Us